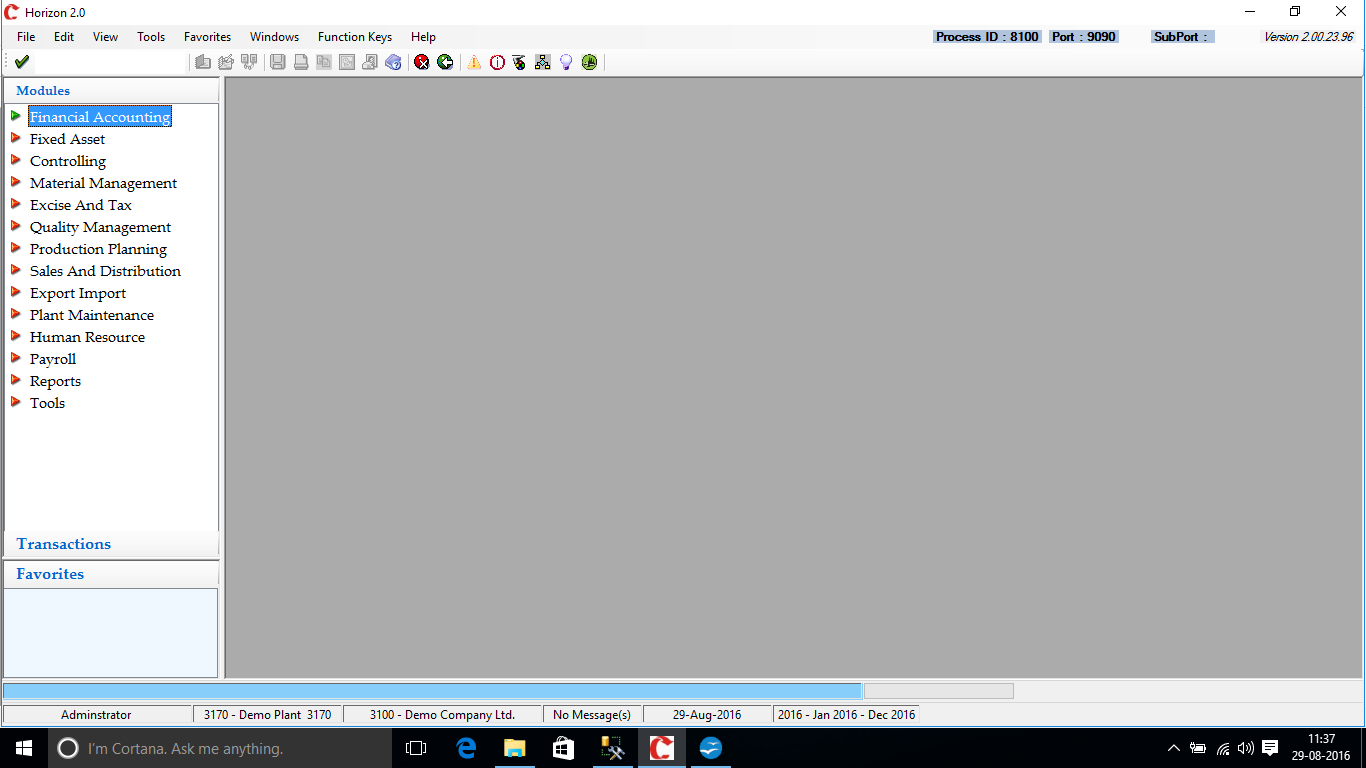

Horizon is an ERP Software designed for both Large as well as small and medium business enterprises. The system is an outcome of functional inputs from ERP experts with vast experience and also a pool of technical experts. The system encompasses some of the global best practices seamlessly synchronized with typical SME processes.

Standard modules like Finance & Accounts, Fixed Assets, Sales & Distribution, Production Planning & Control, Quality Management, Product Costing, Cost-Center Accounting, Materials Management & Inventory Control, etc. are incorporated in the package.

Horizon is an ERP Software designed for both Large as well as small and medium business enterprises. The system is an outcome of functional inputs from ERP experts with vast experience and also a pool of technical experts. The system encompasses some of the global best practices seamlessly synchronized with typical SME processes.

Standard modules like Finance & Accounts, Fixed Assets, Sales & Distribution, Production Planning & Control, Quality Management, Product Costing, Cost-Center Accounting, Materials Management & Inventory Control, etc. are incorporated in the package.

Some characteristics of the package are

- Easily Customizable

- User-friendly interface

- Easily upgradeable and modifiable in case of changes in business process

- Preserves data security and integrity

- Rugged and reliable

- Vast Functionality incorporated to cater to needs of diverse business processes

Salient common features of the System

- Modular integration eliminates duplication of data

- Adaptability to any organizational structure: Single-company, multi-company, multi-division and multi-departmental

- Accounting and consolidation at company as well as group level

- Multiple currency system enables maintenance of accounts in foreign currency and provides for tracking of exchange rate fluctuations

- Classification of Inventories according to various groupings / classes

- Transaction flow traceability / tracking

- User-defined electronic approvals eliminates paperwork and delay

- Multi-Language Support

- User Level Screen settings like Change of Color, Caption, Language, Font etc.

- Secure from unauthorized access and Approvals in Transactions

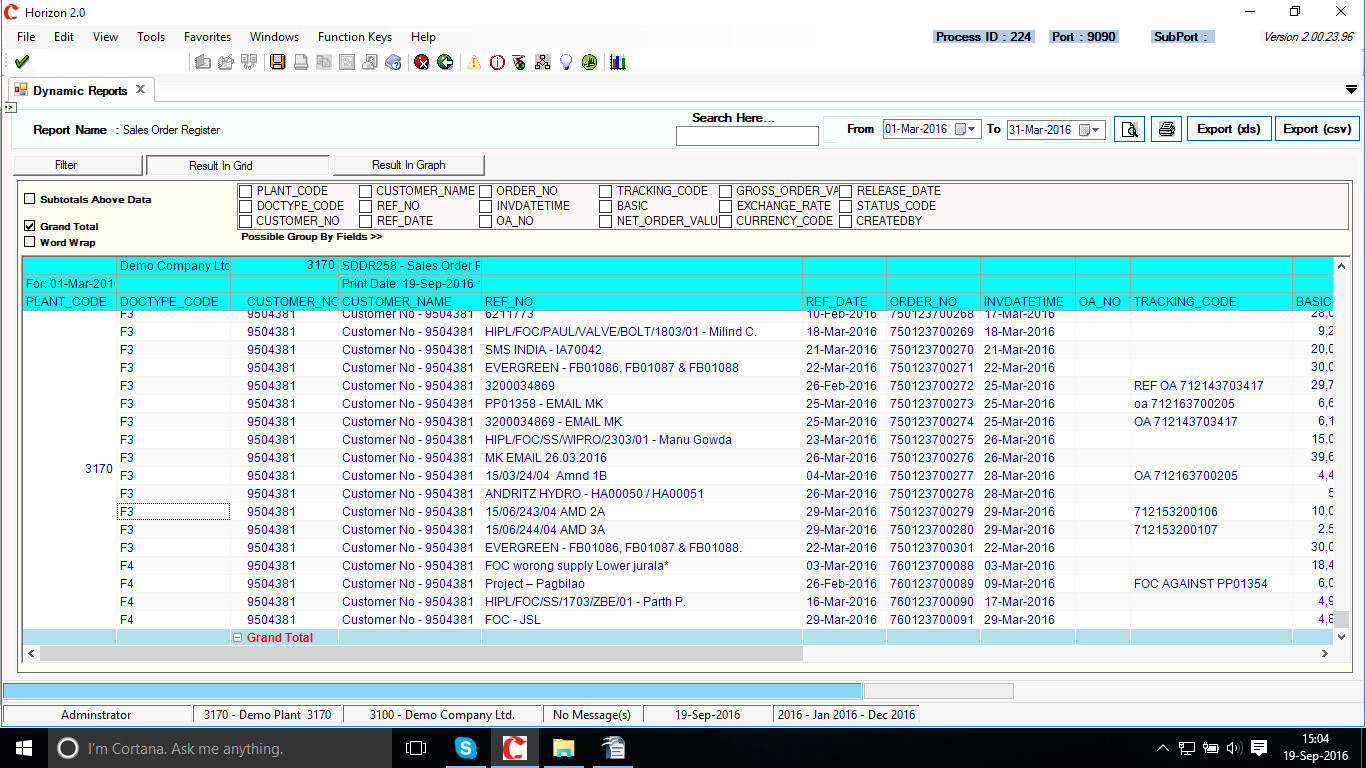

- Dynamic Reports: You can generate immediate run-time customized reports (which can then be exported to MS-Excel). You can define the criteria, grouping, fields to be displayed and their order.

- Transaction inquiry – Period, by document number

- Swipe-card / Bar-code integration

- ISO specified Reports

- Integration with POP3 (e-mail) server

- Complete manufacturing cycle with MRP

- Ability to communicate with external / legacy systems

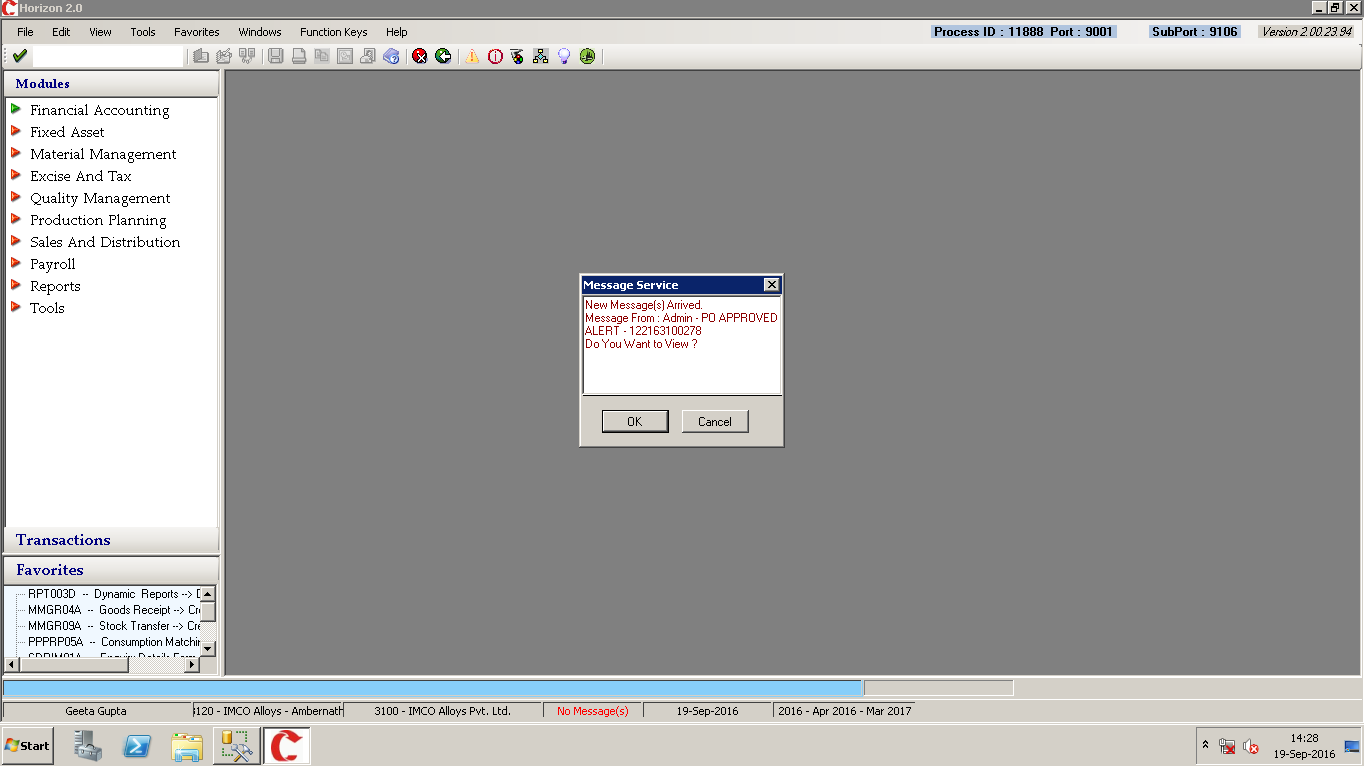

- Inter-user messaging system

- User defined alerts

- User-customizable Front-end interface and On-line help

- User-defined error messages, Reasons and Actions

- User-definable multilevel authorization security features

- Executive Information System

Finance & Accounts

- General Ledgers

- Accounts Receivables

- Account Payables

- Bank Accounting

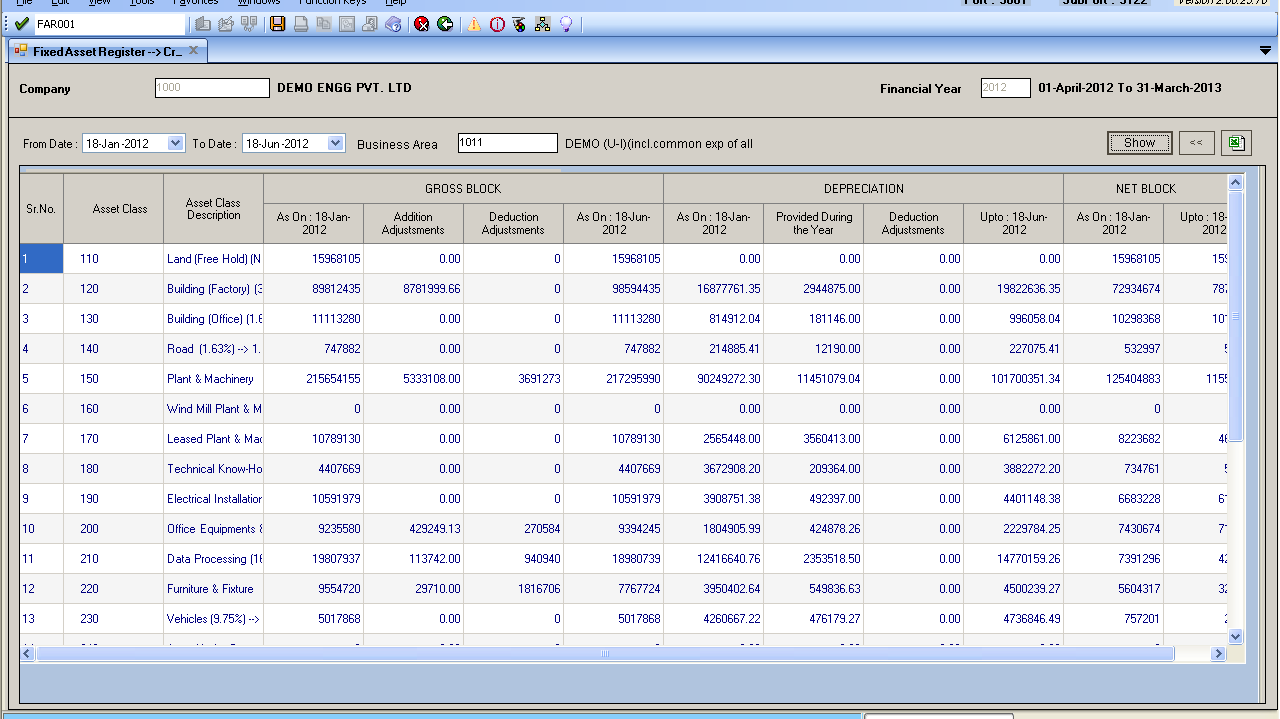

- Fixed Asset Management

- Cash Journals

- Prepaid Expenses

- Exchange rate fluctuations & Forex revaluation

- Inventory Accounting

- Inter Unit Transactions

- TDS, GSTand other statutory Functionality

- Actual / Standard Costing, Variance Reports

- Fully Customizable Balance sheet with drill down

- Business Area wise Reporting and Financial Consolidation

- GL Budgets

- Capex Budget & Control

Controlling

- Cost Center Accounting

- Overhead Cost Calculation

Sales & Distribution

- Support of Both Make to Order and Make to Stock Functionality

- Inquiry and Quotation Management

- Customer Specific Pricing for the Product

- Credit Control using financial Instruments or Credit limits

- Sales Commission Calculation

- Export Functionality and Documentation

- Order Tracking and Booking

- Packing Material Management

- Order Visibility across Inventory, Manufacturing & Shipping.

- Customer Complaint Processing including Goods Return

- After Sales Service & Repairs

- Free and Sample sales

- Sales Returns & Replacements

- Service Invoices

- Analytical & Transaction reports on Customer, Order Number, Product Group & Sales

- Stock Availability check during order booking.

Material Management

- Procurement Process

- Requisitions

- RFQ , Quotation & Quotation Analysis

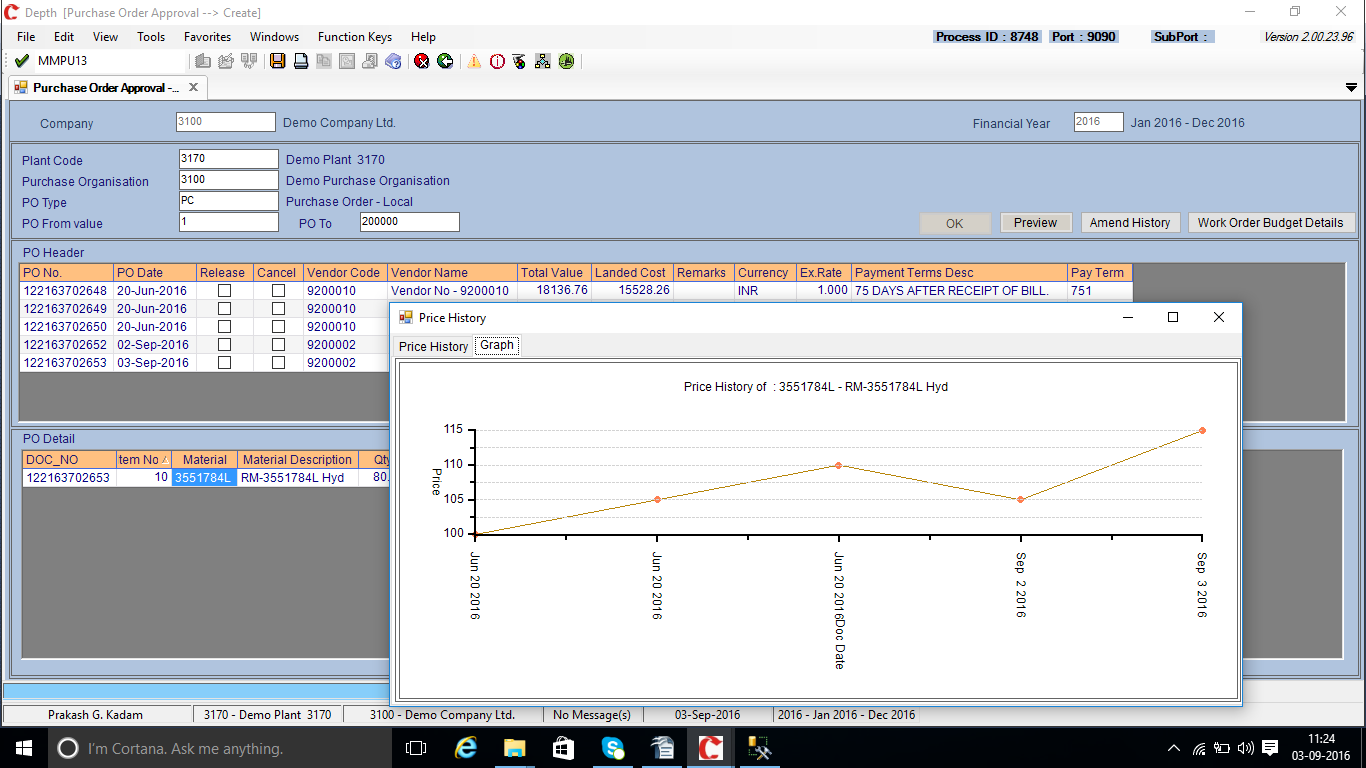

- Purchase Orders with Amendments

- Provision for Returns and Shortages

- Landed Cost calculations

- Inbound / Outbound SubContracting

- Inventory Management

- Multiple UOM’s

- BarCoding Interface to manage raw materials, WIP and finished products

- Raw Materials and Finished Goods control by order / Batch / Lot No

- Goods and materials can be transferred between various legal/global entities

- Batch & Serial controlled materials supported by full transaction history and expiry date

- Batch Characteristics and Material Characteristics

- Bin Management System

- Batch Recall Facility for Problematic Batches

- Stock Valuation

- Uploading of Documents (e.g. Scanned Test/Quality Certificates etc)

Quality Management

- Inbound Material Check for Quality (Raw Material, Subcontracted Material, repairs, etc.)

- Outbound Material Check for Quality

- Inspection Plan, Result Recording & Usage Decisions.

- Rejection Analysis and Returning to Main Vendor from any stage

- WIP Material Check for Quality

- Quality Certificates

- Quality Analysis & Reporting

- Test equipment calibration

- NonConfirmation Report

- Sample Testing analysis

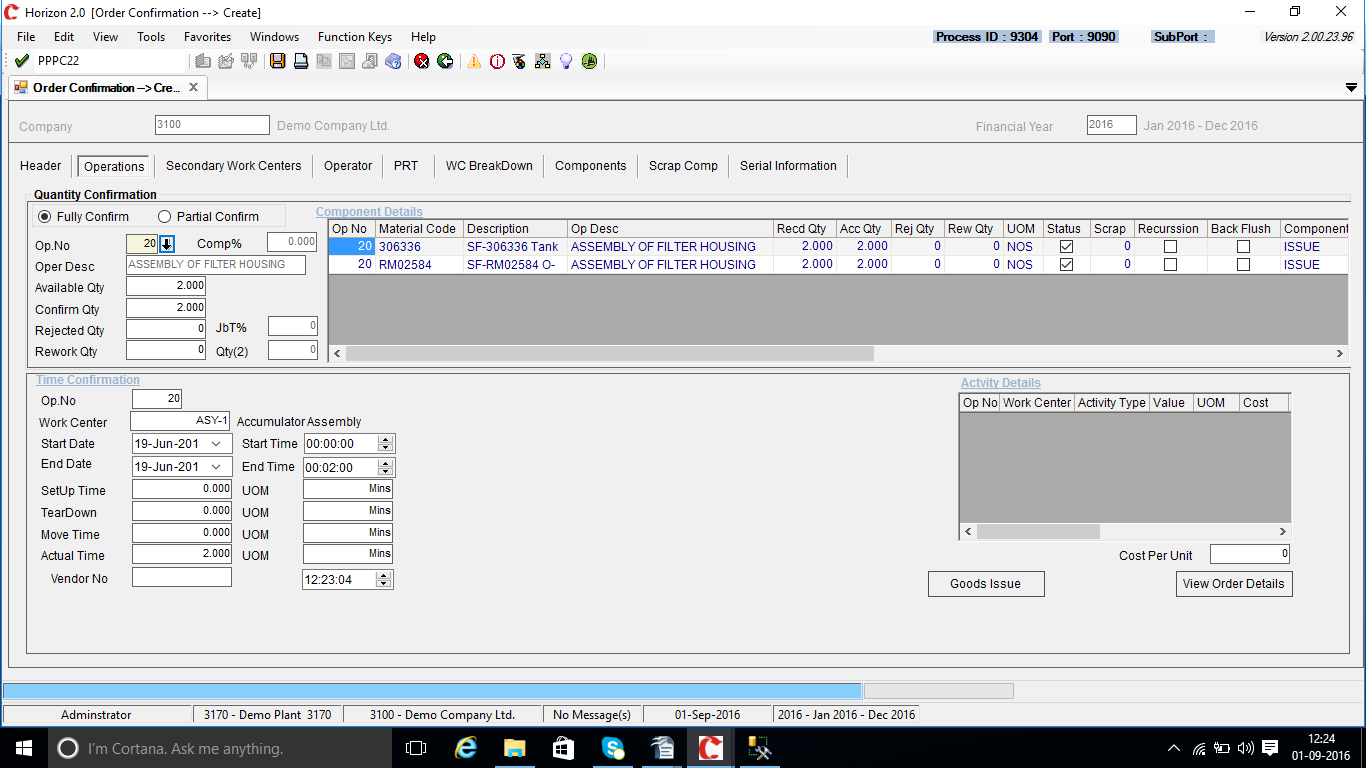

Production

- Bill of Material which includes all materials required for production

- Routings (structured and inprocess or shop order format)

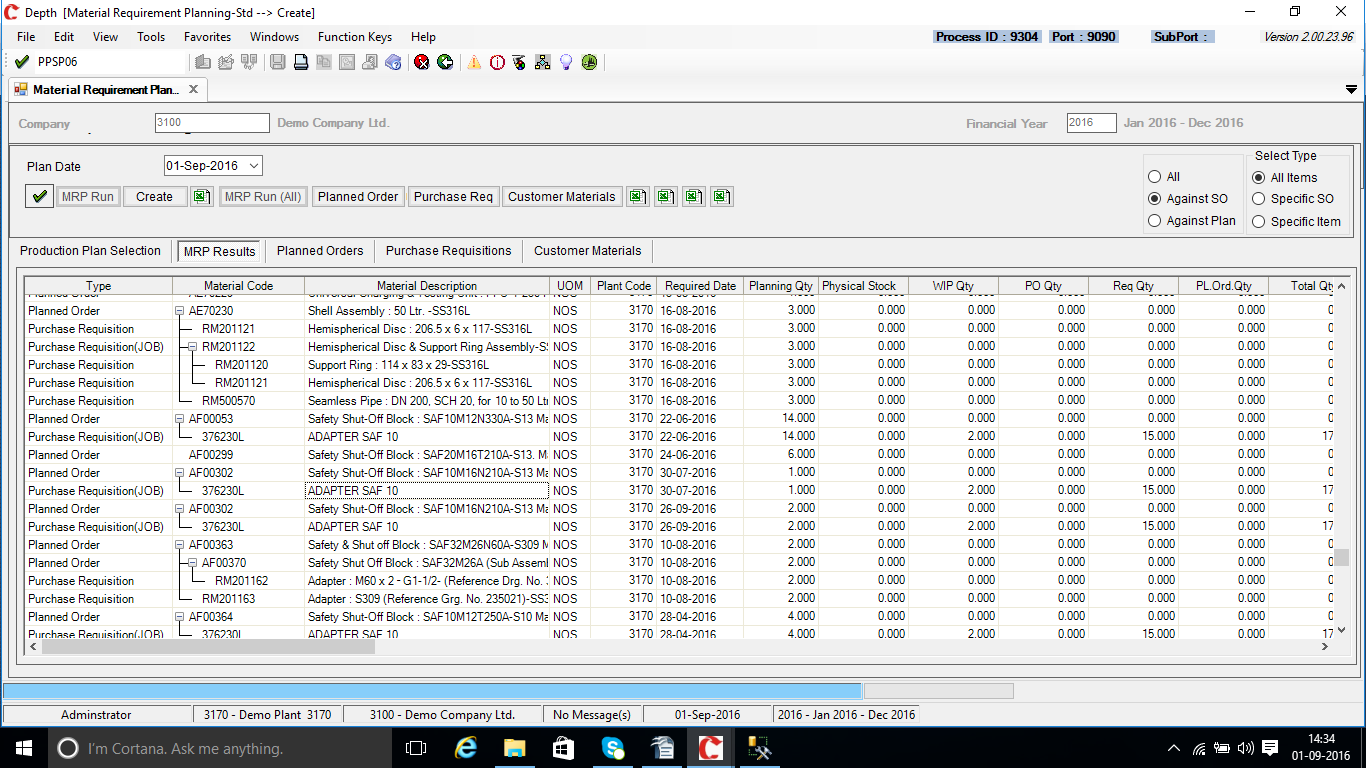

- Material Requirement Planning

- New Product Development

- Sales OrderCosting, Production Order Costing and ByProduct Costing

- Production accountability, Efficiency, Utilization, Idle time.

- In Process Sub Contracting

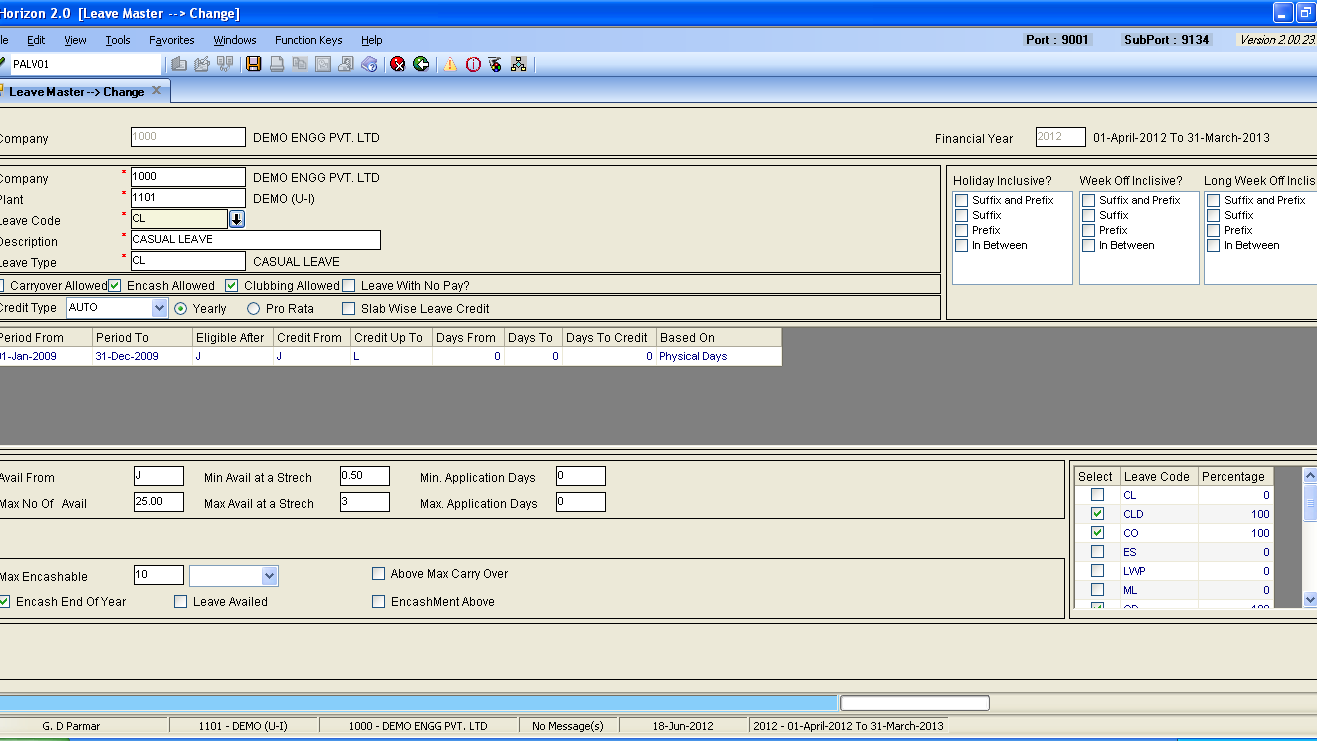

Payroll

- Comprehensive Employee details (Personnel Details, Company, Statutory, Bank)

- Robust Income tax processing as per latest IT rules & Regulations

- Meet Statutory Requirements like PF, ESIC etc...

- Easy Interface for integration with Production Data of any ERP

- Wage/Incentive calculation with Piece rate processing

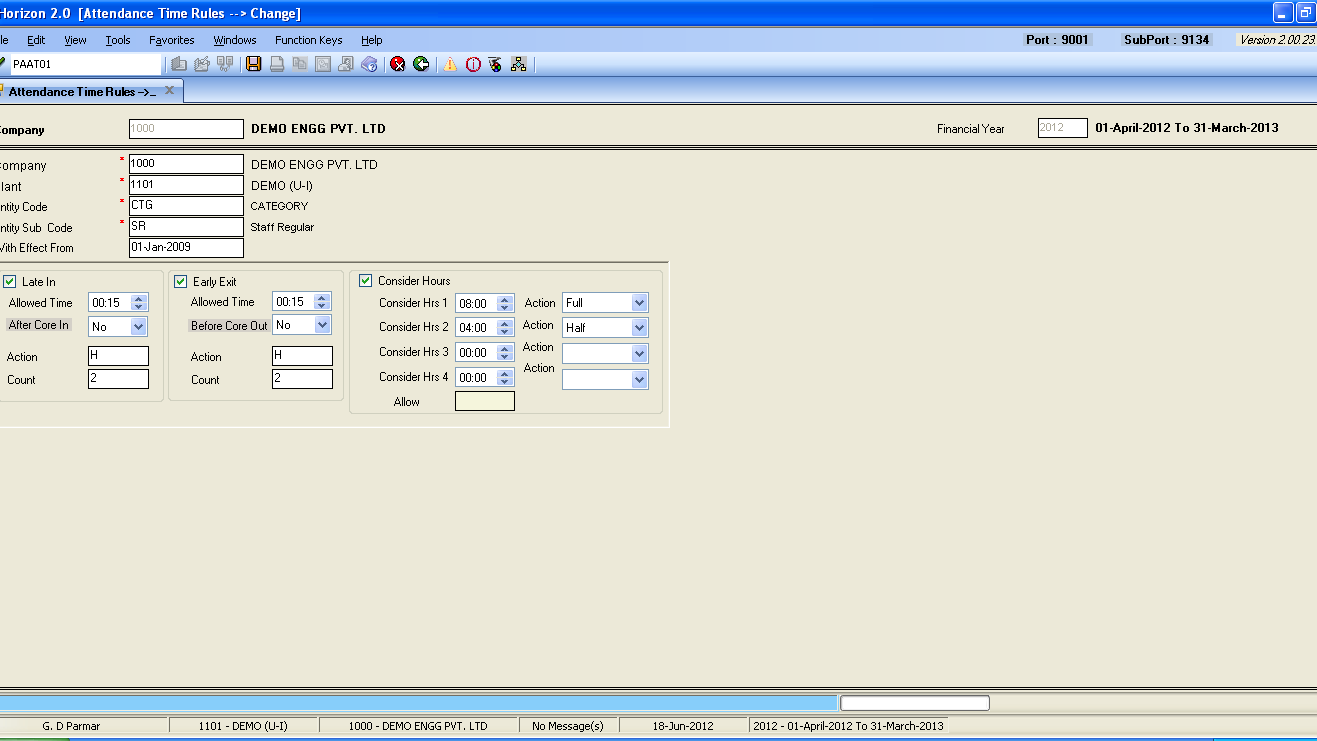

- Customizable Attendance & Overtime Calculations

- Contractual employees accounting

- FI Integration

Case Studies of some of our ERP Implementations.

- Financial Accounting including Fixed Asset Management

- Costing (Materials & Overheads)

- Materials Management (Purchase, Inventory & Stores)

- Sales & Distribution (Inquiry to Invoicing & Returns)

- Customer Service

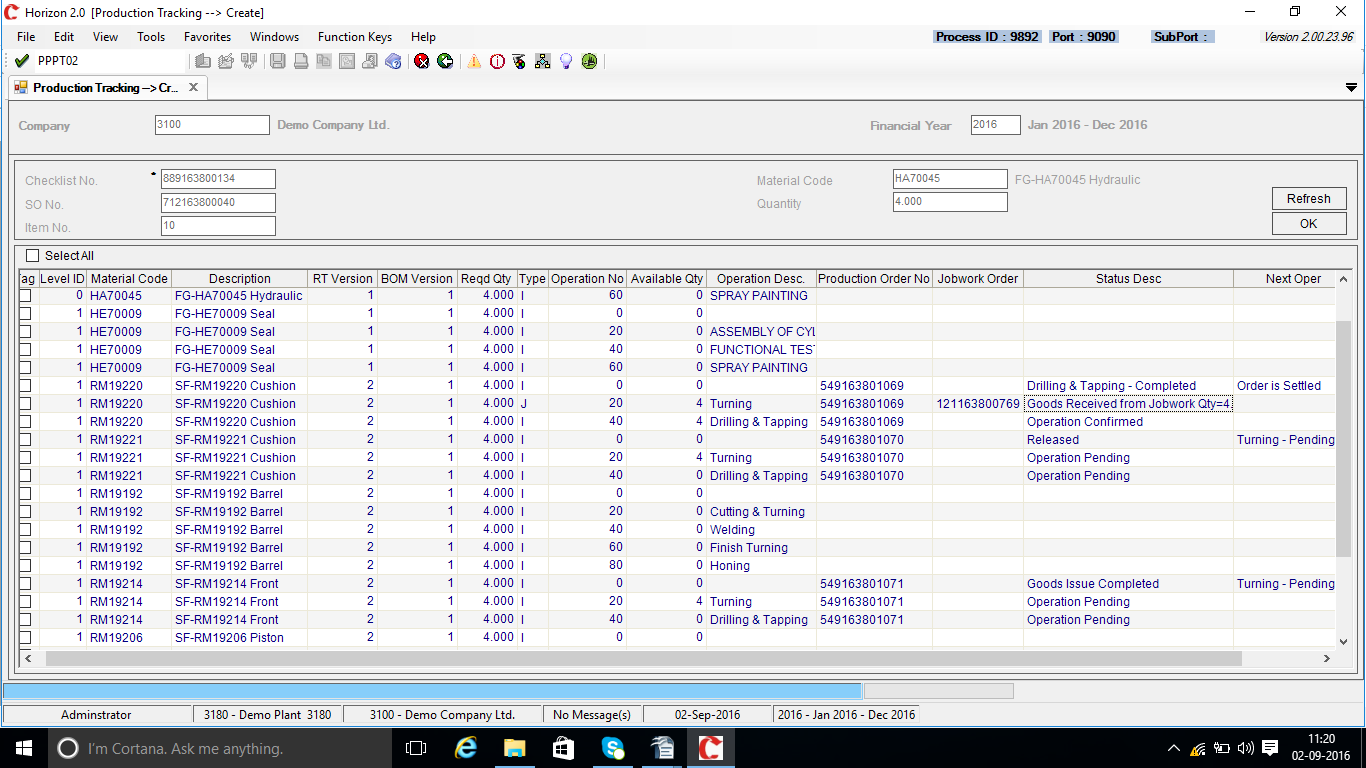

- Production Planning & Control (Job based Manufacturing, Discrete & Repetitive)

- Quality Management

- Payroll

- EXIM (Export Documentation for Normal Unit, SEZ & EOU)

- Alerts & MIS

- Configuring Job based Manufacturing, Discrete & Repetitive Manufacturing

- Job Tracking & Costing including Material cost & overheads

- EXIM documentation & Processes for Normal, EOU & SEZ

- Stock Transfer Scenarios taking care of all statutory requirements for EOU & SEZ

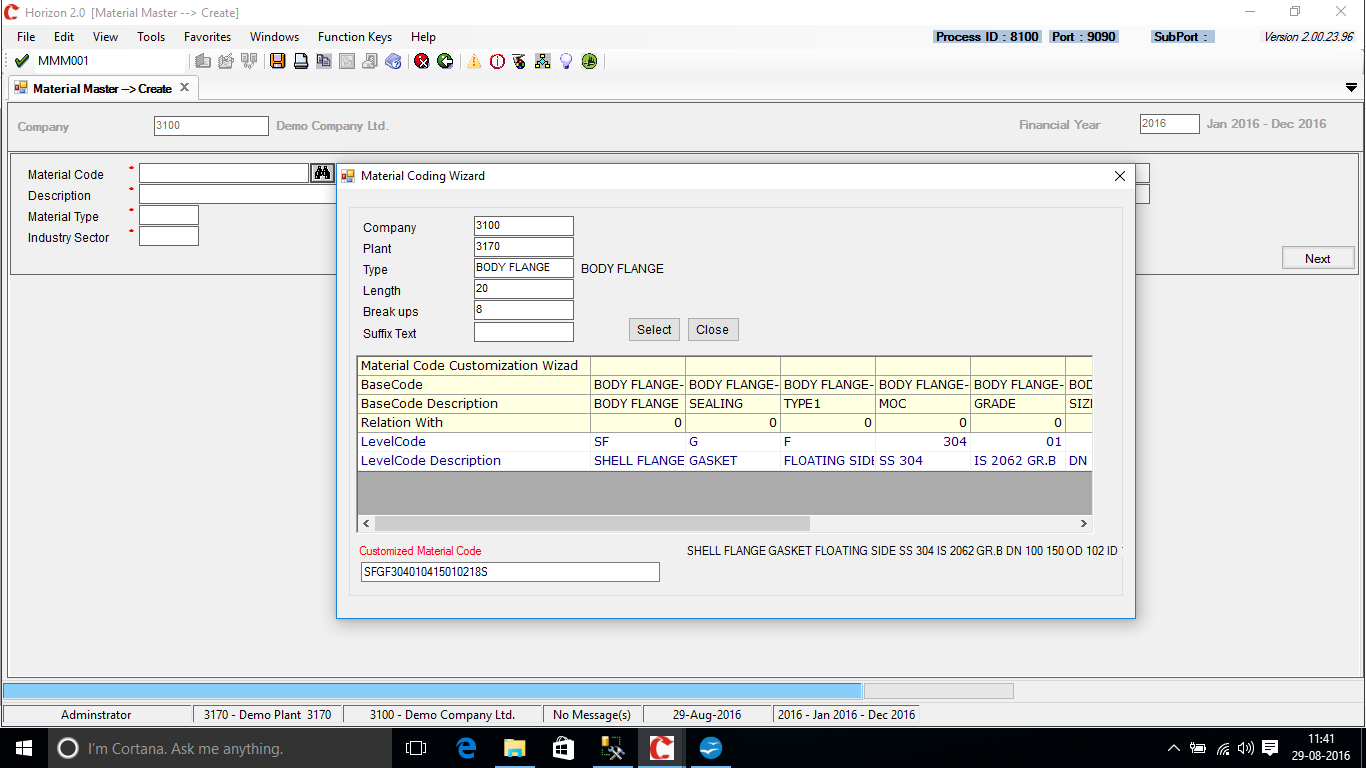

- Material Codification Wizard

- Batch Management & Serial Management for better Inventory Tracking

- Overhead Costing actual & Budgeted

- Statutory requirements for Income Tax, Service Tax, Excise etc.

- Document Attachments and viewing

- Checklist for Purchase & Sale Transactions

- Purchase Quotation Comparisons & Vendor Rating

- Test Certificate attachment and validations

- Material Requirement Planning & ROL Planning

- Detailed BOM & Routing to enable better tracking of Productions

- Procurement, Production &Inprocess Quality and Calibration of Tools

- Inward and outward Subcontracting

- Customer Servicing with free Spares, replacements & Service Billings

- Breakdown & Preventive Maintenance

- Alerts for Key activities requiring action

- Company level & Business Area, Segment wise Financial reporting

- Detailed & exhaustive MIS

- Financial Accounting

- Costing (Materials)

- Materials Management (Purchase, Inventory & Stores)

- Sales & Distribution (Inquiry to Invoicing & Returns)

- Customer Complaints

- Production Planning & Control (Discrete Manufacturing)

- Quality Management

- Alerts & MIS

- Configuring Discrete Manufacturing

- MTO Scenario. Net Requirement Based MRP configured and in use extensively

- Material Codification Wizard

- Batch Management & Serial Management for better Inventory Tracking

- Statutory requirements for Income Tax, Service Tax, Excise etc.

- Document Attachments and viewing

- Checklist for Purchase & Sale Transactions

- Purchase Quotation Comparisons & Vendor Rating

- Material Requirement Planning & ROL Planning

- Detailed BOM & Routing to enable better tracking of Productions

- Procurement, Production &Inprocess Quality and Calibration of Tools

- Customer Servicing with free Spares, replacements & Service Billings

- Alerts for Key activities requiring action

- Company level & Business Area, Segment wise Financial reporting

- Detailed & exhaustive MIS

- Financial Accounting including Fixed Asset Management

- Costing (Materials & Overheads)

- Materials Management (Purchase, Inventory & Stores)

- Sales & Distribution (Inquiry to Invoicing & Returns)

- Customer Complaints

- Production Planning & Control (Process Manufacturing)

- Quality Management

- Payroll

- Alerts & MIS

- Configuring Process Manufacturing

- Recipe Management

- Configured Recipe confidentiality to manage secrecy of Recipe

- MTO & MTS Scenario with forecast planning

- Material Codification Wizard

- Batch Management

- Statutory requirements for Income Tax, Service Tax, Excise etc.

- Checklist for Purchase & Sale Transactions

- Purchase Quotation Comparisons & Vendor Rating

- Procurement, Production &Inprocess Quality and Calibration of Tools

- Customer Complaints

- Alerts for Key activities requiring action

- Company level & Business Area, Segment wise Financial reporting

- Detailed & exhaustive MIS

How we shall deliver :

- As-Is & To-Be Study

Our Vertical Functional experts shall initially do a detailed As-Is Study and note down the requirements and scenarios in detail. We shall also demonstrate our Vertical Template with all required configurations for particular Industry so that we can get better input from the Key Users. The As-Is & To-Be requirements shall be documented and the same circulated for sign-offs. The Hardware sizing Document and Base Master Templates shall be given to the Client Project Manager.

- Configuring & Customizing

This phase shall be handled at our Development Centre. The ERP Template shall be further configured and required developments done and reports set as per requirements noted in the Study. The same shall be tested with dummy Master data.

- Pilot Demo & Realization

The configured Customer Template shall be installed on demo server at client end. The template shall be demonstrated to the Key Users with sample data for all scenarios and processes as listed during the study. Key Users shall approve and sign-off the realization document and confirm that system has met the requirements.

- Pre-Live Activities

The Key Users shall do the Module and integration testing of ERP. Masters that have been given by the Key users in templates shall be uploaded. Testing will happen on the actual masters given. Once testing is over, Key users with support of CTPL team shall do the end user training. All required Server and Client Application Installations shall be done. Open Items (GL Balances, Outstanding, Stock) etc shall be uploaded. All required Pre-Live Check list activities shall be done. All required Document outputs shall be checked.

- Go-Live & Onsite Support

On predefined Live Date the system shall be considered to have gone live. All transactions shall happen through the ERP from that given date. CTPL team shall ensure minimum down time for the period. CTPL team shall help the client to establish an internal help desk for ERP and also setup the Support framework for handling remote support later on.